Hydro-boost brake boosters use the pressure of the power steering pump to power the brake booster. These systems can be mysterious to the untrained technician because part-swapping will not solve some brake issues. The booster is essentially a power steering unit that supplements the driver’s input. Hydro-boost was first introduced to solve issues associated with the safety and fuel-efficiency mandates in the 1970s. These worked because they produce more boost than a. Second, the units are compact enough to fit in spaces a vacuum booster can’t, like on vans. Lastly, they aid diesel vehicles that can’t produce enough engine vacuum.

Hydro-boost vehicles are not hard to work on and typically don’t require special tools, but they do require service information and a working knowledge of the system. Listen Properly operating hydro-boost units will produce certain noises not heard in vacuum booster systems.

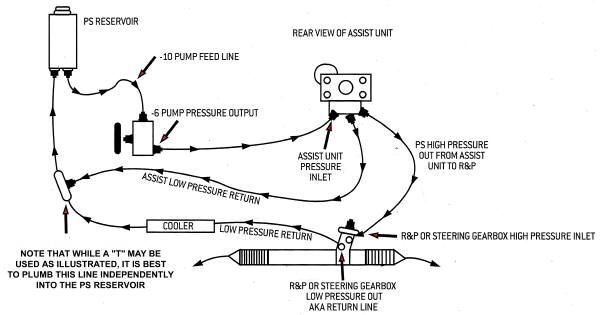

Eugene hecht physics pdf file. Installing Hydro-Boost Return Lines and T-ing into Power Steering Return Matt Sweeting's Power Brake TV. Unsubscribe from Matt Sweeting's Power Brake TV?

These noises occur, for the most part, when the brake pedal is manipulated in a manner not associated with everyday driving habits. The general categories of normal operating noises are hissing and clunk/clatter noises. Basic Function Test To check if a hydro-boost system is functioning, perform this test: • With the engine off, pump the brake pedal until it is hard. • Start the engine. • Proper operation should result in the brake pedal sinking down and then pushing back up against your foot.

The sinking of the pedal when the engine was started is a result of the power chamber being pressurized. Once the is at full pressure, the pedal will push back against your foot pressure. This test will only verify if the pump, hydro-boost unit and reserve are working. This test will not diagnose performance problems of certain customer complaints.

Check the Service Information for Correct Test Procedure The basic function test can only tell you if the system is functioning — it will not tell you how well the system is functioning. Many OE test procedures have specific rpm ranges and steering wheel movements to determine the health of the system. Look them up. Hoses Are Safety Items are just as important as brake hoses. Inspect all power steering hoses, which include hoses that connect only the power steering gear to the pump.

If a leaking or soft, spongy hose is found anywhere in the system, replace all hoses. If any single hose is bad, the others are likely ready to fail. Not all hose defects can be detected from outward inspection because they usually fail from the inside out. Deteriorated hoses produce debris, which will damage all parts of the system, including the hydro-boost unit. Flush the System The spool valve fits into a precisely machined bore that is part of the hydro-boost housing.

The fit between the spool valve and the bore is such that it creates a seal while allowing enough fluid between the lands and bore to provide lubrication. The tolerances of the moving parts inside the hydro-boost are such that even a small amount of contaminants can cause a malfunction. This is especially true of the spool valve.